Reverse Logistics Mishaps: How One Wrong Return Can Derail Your E-Commerce Operations

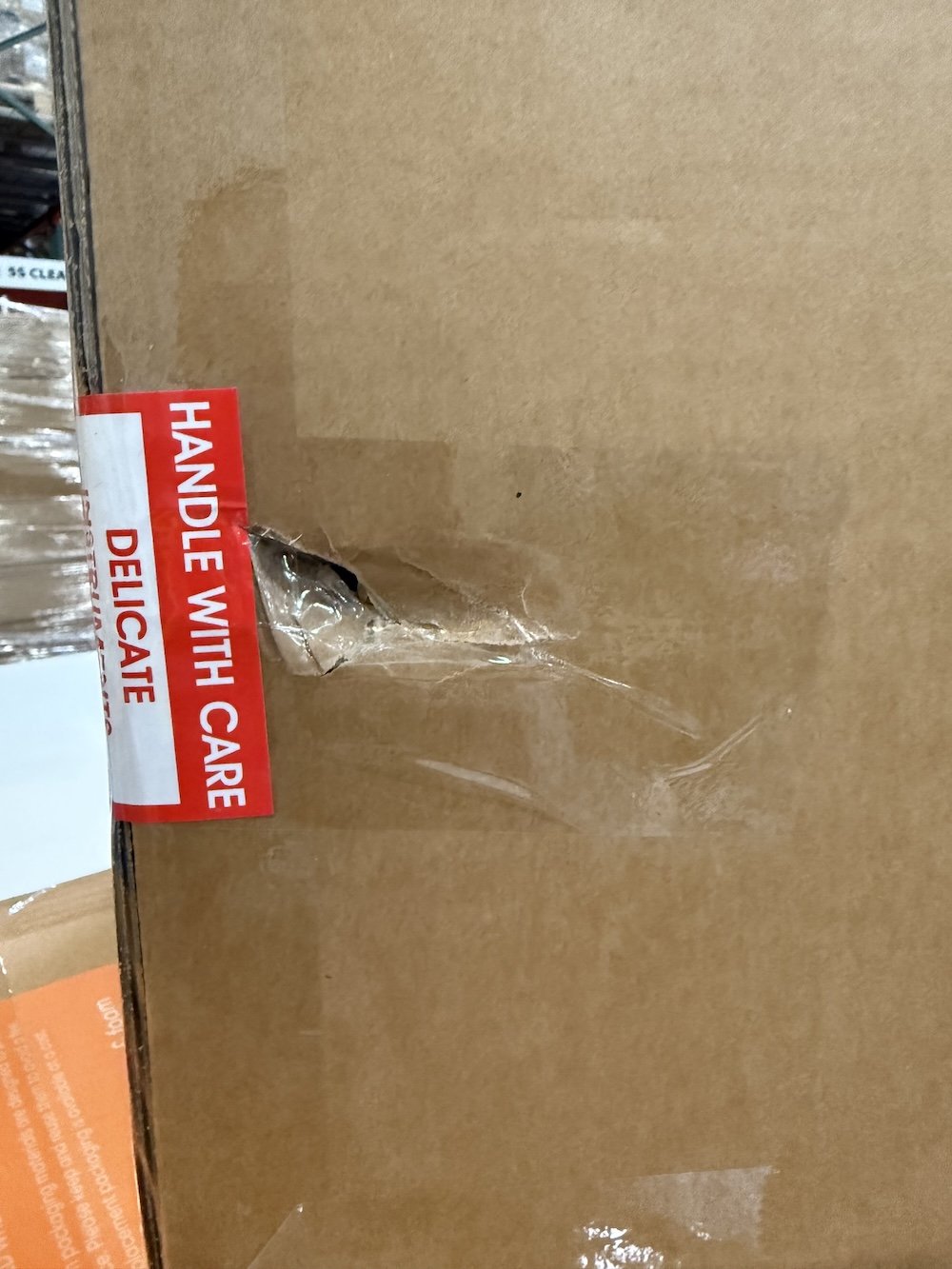

E-commerce returns are inevitable, but when they aren’t handled properly, they create financial waste, inventory errors, and a frustrating customer experience. In some cases, they can even turn into outright logistical disasters.

In one example of a recent customer return that arrived at our facility: a package mistakenly contained two handgun magazines and live ammunition. It was meant for an entirely different recipient (we don’t ship firearms or ammo). Due to the customer mislabeling their shipments at the local FedEx Office, this box ended up in our returns processing center—an alarming but surprisingly common example of how returns can go off the rails.

For e-commerce brands, especially those dealing in high-value, complex, or warranty-sensitive products, an organized, efficient, and error-proof reverse logistics strategy is essential. Without it, misplaced returns, improper restocking, and customer disputes can spiral into costly problems.

This post will break down how to prevent costly mistakes in reverse logistics, from inventory accuracy to quality control, product testing, and customer centric returns management.

1. The Hidden Dangers of Poor Returns Management

Many brands view returns as a minor operational hassle, but when managed poorly, they lead to significant revenue loss, stock inaccuracies, and dissatisfied customers. A single mishandled return can have far-reaching consequences, including:

A. Financial and Inventory Impacts

Misplaced inventory: A returned item that isn’t logged correctly can be lost in your warehouse indefinitely.

Missed profit opportunity: Functional products might be incorrectly classified as defective and mistakenly discarded. Products that should fail cosmetic inspection or functional test may make their way too far into the refurbishment process resulting in unnecessary expense.

Stock inaccuracies: If returned goods are not properly accounted for, new inventory orders may be miscalculated, leading to stockouts or overstocking.

Example: A customer returns a fully functional smartphone, but due to incorrect logging, it’s marked as non-repairable and scrapped. That’s a direct revenue loss that could have been avoided.

B. Customer Experience (CX) Risks

Customers expect fast, seamless returns. If an e-commerce brand mishandles returns, customers lose trust, leading to:

Negative reviews and brand damage

Chargebacks and disputes

Loss of repeat customers

Example: If a customer sends back a defective gaming console and is mistakenly issued a restocking fee or receives the wrong replacement, frustration grows—and so does the likelihood of them never shopping with you again.

2. The Role of a Strong Customer Experience (CX) Strategy in Returns Management

Returns aren't just about logistics—they are an extension of the customer experience. A confusing, slow, or frustrating return process pushes customers away.

A. Why CX and Returns Are Inseparable

A well-designed returns process should be:

✅ Clear – Customers should know exactly how to return a product and what to expect.

✅ Fast – The fewer steps, the better. Complicated return forms or delays kill retention.

✅ Reliable – Every return should be processed consistently and correctly, without surprises or mistakes.

A strong CX strategy ensures that returns are handled efficiently, in a way that minimizes costs while keeping customers happy.

B. How to Balance Cost-Effectiveness with Customer Satisfaction

Many brands struggle to strike the right balance between reducing returns costs and providing a great customer experience. Here’s how to achieve both:

Use pre-paid return labels & self-service portals – This reduces inbound customer service inquiries.

Offer real-time return status updates – Keeping customers informed prevents unnecessary “Where’s my refund?” support tickets.

Standardized return policies – A clear policy on return eligibility prevents disputes and confusion.

Efficient warehouse workflows – The faster a return is inspected and restocked, the sooner a refund or replacement can be processed, and the sooner any potential value can be recouped from returned inventory.

C. Returns Triage: The First Step to an Efficient Process

Sorting returns properly as soon as they arrive prevents delays, misplacements, and unnecessary costs.

Implement a Return Merchandise Authorization (RMA) system to prevent fraudulent returns.

Categorize returns upon receipt (e.g., unopened, functional, needs repair, unsellable).

Designate warehouse areas for different return categories to prevent errors. A strong WMS is critical here.

🚀 Key takeaway: If your warehouse doesn’t sort returns correctly at intake, the entire process becomes a mess.

3. The Pillars of Product Inspection, Functional Testing, and Refurbishment

Reverse logistics isn’t just about getting items back—it’s about maximizing value recovery through inspection, testing, and refurbishment.

A. Product Inspection

Before any item can be restocked or refurbished, it needs a thorough inspection. Standardizing inspection protocols ensures that every return is assessed the same way, reducing human error.

Best practices:

✅ Use barcode scanning & especially serial number validation to ensure items match the RMA request.

✅ Define clear SOPs for inspecting different product categories (e.g., electronics, apparel, medical devices).

✅ Train employees to spot warranty fraud or damaged goods misrepresented as functional.

In cases where prohibited or unexpected items are received—like our handgun magazines and live ammunition mix-up—there must be a secure process for handling misrouted returns.

B. Cosmetic Inspection: The First Step in Returns Processing

Before functional testing begins, cosmetic inspection determines whether a returned item is in good enough condition to be resold or requires further processing.

A well-structured Standard Operating Procedure (SOP) for cosmetic inspection should include:

1️⃣ Visual Damage Check: Inspect for cracks, scratches, dents, or other signs of mishandling. Be very specific with the instructions for your warehouse. In your instructions or SOP, do provide specifics such as “fail the unit if any single scratch is more than 1 centimeter in length, more than 2 millimeters in width, or if more than one scratch meeting the same criteria appear within 10 centimeters of each other.

2️⃣ Packaging & Label Inspection: Ensure the product is in its original packaging, with correct labeling.

3️⃣ Completeness Check: Confirm that all accessories, manuals, or components are included.

4️⃣ Authentication & Branding: Verify authenticity, especially for high-value or branded items.

🚨 If a product fails cosmetic inspection, there is often no need for functional testing, as it is unlikely to be resold as "like-new”.

C. Functional Testing: Ensuring Only Quality Products Go Back to Stock

A product may look fine externally, but testing may be required before restocking or resale. Examples:

Check battery life, connectivity, and internal components.

Run functional tests on key parts (e.g., motors, displays, buttons).

Verify sensors, software functionality, and external condition.

Without functional testing, you risk restocking defective products—leading to even more returns.

D. Refurbishment and Resale: Maximizing Recovery Value

If an item fails functional testing, it enters a structured refurbishment process to be repaired and resold.

Refurbishment workflow:

1️⃣ Diagnose the issue

2️⃣ Repair or replace defective components

3️⃣ Run final quality assurance testing

4️⃣ Repackage & certify as refurbished

5️⃣ Resell or redistribute for secondary use

Unusable products should be harvested for components, recycled, or disposed of responsibly.

E. Why a Warehouse Management System (WMS) Is Critical for Triage & Binning

A Warehouse Management System (WMS) or other returns tracking software plays a crucial role in this step. If the system doesn’t correctly log whether an item passes or fails cosmetic inspection, costly errors happen.

Incorrect binning leads to misclassified inventory (e.g., a defective item accidentally gets restocked).

Automated tracking ensures accurate processing and helps direct products to the right next step (e.g., restock, refurbish, recycle).

🚀 Key takeaway: A WMS-driven triage system ensures that returns are categorized correctly every time, preventing costly mistakes.

4. Establishing SOPs and Auditing Quality Control in Returns Processing

A. Why SOPs Are Critical in Reverse Logistics

Without clear Standard Operating Procedures (SOPs), returns management becomes inconsistent and prone to errors.

An effective SOP should cover:

✅ Inspection criteria for each product category

✅ Testing protocols before restocking

✅ Refurbishment workflows

✅ Inventory reconciliation and quality assurance

B. Quality Auditing in the Warehouse

Regular audits ensure that returns are processed correctly and that inventory levels remain accurate.

How to audit effectively:

Conduct random sample audits on processed returns.

Track warehouse accuracy metrics, such as return-to-stock error rates.

Provide ongoing employee training to reduce processing mistakes.

A structured audit system keeps inventory in check, ensures compliance, and prevents losses.

5. How a 3PL Like Rush Order Can Prevent Costly Reverse Logistics Errors

Many brands don’t have the internal resources to manage returns efficiently at scale. That’s where third-party logistics (3PL) / returns management companies like Rush Order come in.

A. Expertise in Handling Complex Returns

End-to-end returns processing, from inspection to resale.

Experience with high-value, regulated, and complex products.

B. Reducing Risk and Maximizing Recovery Value

Proper inventory tracking and processing accuracy prevent financial losses.

Effective refurbishment programs ensure every item is evaluated correctly before resale.

C. CX-Driven Returns at Scale

Fast, customer-friendly returns processing improves satisfaction.

Seamless integration with e-commerce platforms and customer service teams.

Conclusion: Avoiding Costly Reverse Logistics Disasters

A single return mishap can disrupt operations, hurt inventory accuracy, and damage customer trust. By implementing structured workflows, quality audits, and customer-centric returns policies, e-commerce brands can turn returns from a liability into an opportunity for revenue recovery.

💡 Need help managing complex returns? Rush Order ensures every return is handled with precision.

📩 Contact us today to streamline your reverse logistics operations.